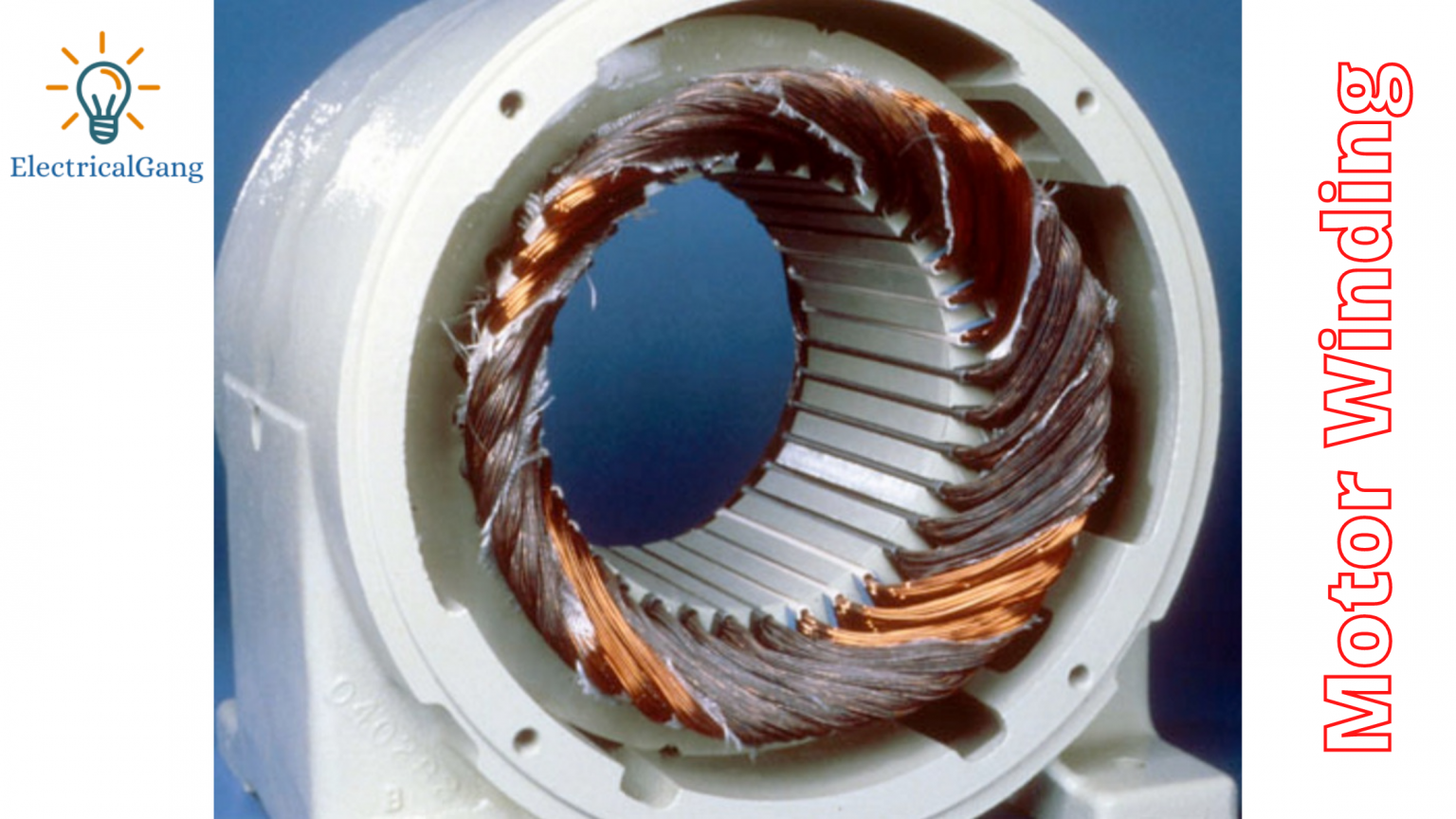

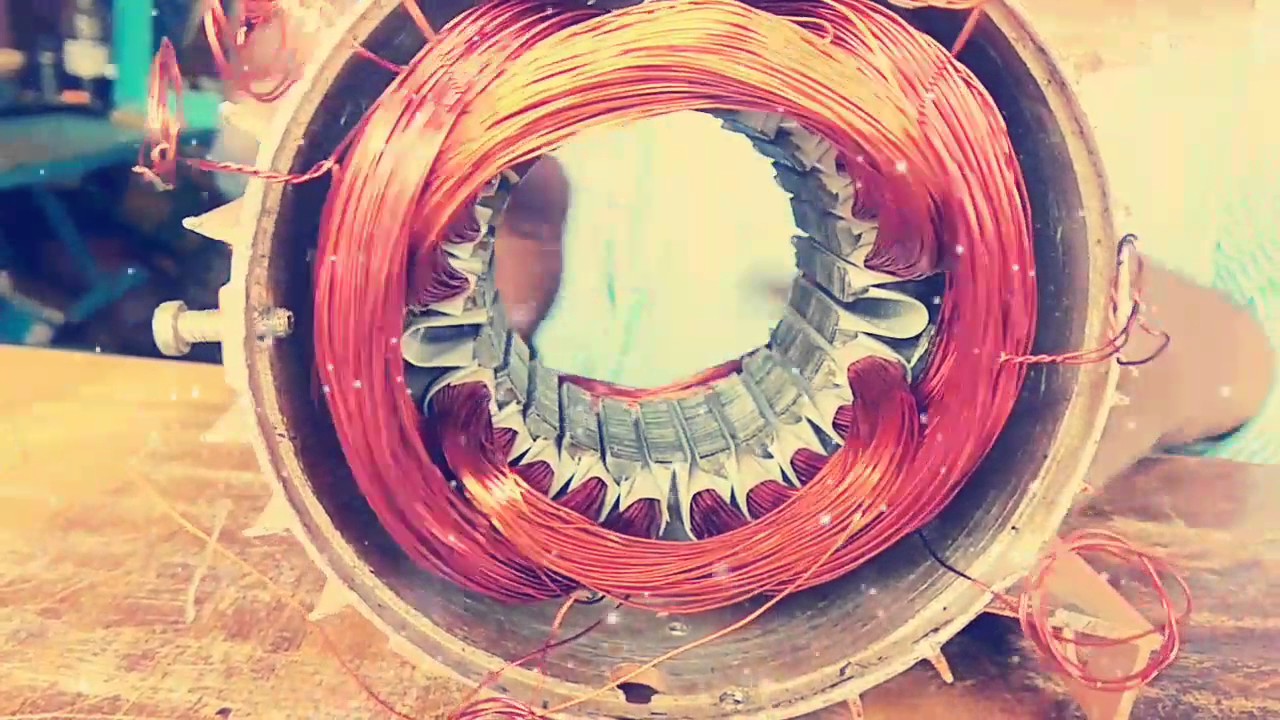

What is motor winding unodarelo

Chuck Yung EASA Technical Support Specialist One of the most misunderstood winding connections is the part-winding start. Many customers (and.

Partwinding connection Electric motors & generators engineering

In this lesson we'll examine part winding reduced voltage starters. Reduced voltage starting methods reduce inrush current and modify acceleration and starti.

Part Winding Starters

Motor Starters Part 1: Direct On-line Motor Starters Part 2: Selecting and Sizing DOL Parts Motor Starters Part 3: Pros and Cons of the Star-Delta Configuration Motor Starters Part 4: Selecting and Sizing Star-Delta Parts Different types of equipment and machines power industries.

How a PartWinding Start Motor Works Ed's Supply Co.

Part winding starting This starting method requires a motor wound specifically for this application. It is not a reduced voltage technique. These special nine lead motors use only a portion (1/2 to 2/3) of their windings during starting. Starting torque is extremely low and the motor is not expected to accelerate.

Starter part winding Series And Parallel Circuits Electrical

Part-winding connection thread237-359153 Forum Search FAQs Links MVPs elinBG (Electrical) (OP) 5 Feb 14 13:56 Hello, How is called this connection I found it on an semi-hermetic compressor it is used for "part-winding start". How does it work? Any information on it will be great www.eldvigateli.com rhatcher (Electrical) 5 Feb 14 20:16

What Is Motor Winding? Types of Motor Winding

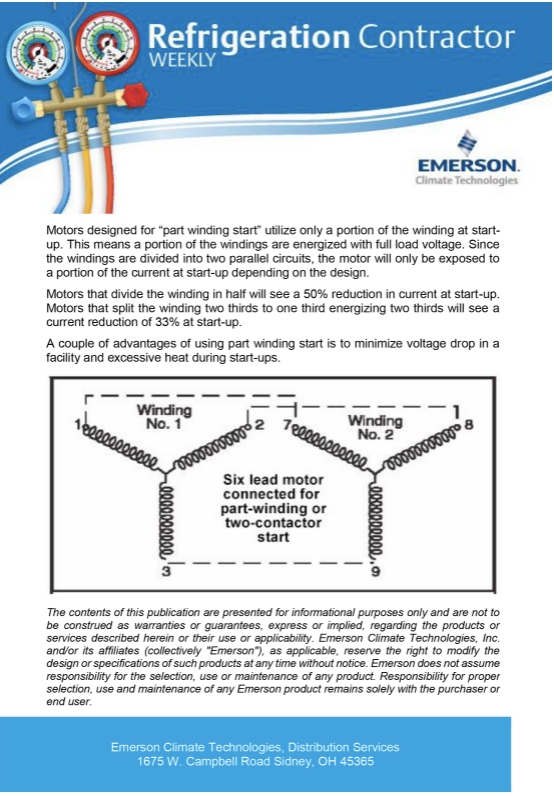

Motors designed for "part winding start" utilize only a portion of the winding at start-up. This means a portion of the windings are energized with full load voltage. Since the windings are divided into two parallel circuits, the motor will only be exposed to a portion of the current at start-up depending on the design.

Part winding o arranque a devanado parcial

A part-winding starter will reduce starting current draw to approximately 65% of normal locked rotor amps, and torque to 45% of normal motor torque. A part-winding starter uses two contactors and a timer. Solid state reduced voltage starters (Soft Starts) utilize solid state devices called Silicon Controlled Rectifiers (SCR's) to increase and.

Part Winding Motor Wiring Diagram Wiring Diagram And 6AD

Also, since some part-winding start motors are numbered incorrectly as 1 to 6, remember the starting method you're using. 9 Leads. If leads are numbered 1 to 9, the motor is typically rated for two voltages and could be designed with either a wye or delta connection. Using the machine on the higher rating, the external connection is the same.

Part Winding Motor Wiring Diagram Wiring Diagram And 6AD

in detail: Section Title Page Number · Starters - A Brief Review 3 · What is Reduced Voltage Starting? 4 · Why is Reduced Voltage Starting Needed? 4 · To Avoid Overloading the Power 5 Distribution · To Avoid Unnecessary Wear and Tear 5 On by Reducing Starting Torque · What Types of Reduced Voltage Starters 6 Are · Primary Resistor 7 ·

What Is Motor Winding? Types of Motor Winding

Part Winding Starters Approximate Dimensions Multispeed Magnetic Starters Application Data Two-Speed Combination Starters Reversing Two-Speed Magnetic Starters Two-Speed Magnetic Starters Approximate Dimensions Lighting Contactors Panelboard Lighting Contactors, Type PB Well-Guard™ Pump Panel Reduced Voltage Type Factory Modifications (Forms)

Part Winding Starters

Part Winding Start (Wye Only) - Single Voltage. Speed: Single. Phase: 3. Voltage: Single. Winding: Y only. Special Feature: Part winding start. Note: Suitable for unit previously approved for part winding start (a standard Star - Y 230/460 9 lead motor may often be used for 230V part winding - a special winding is required for 460V part winding.

How a PartWinding Start Motor Works Ed's Supply Co.

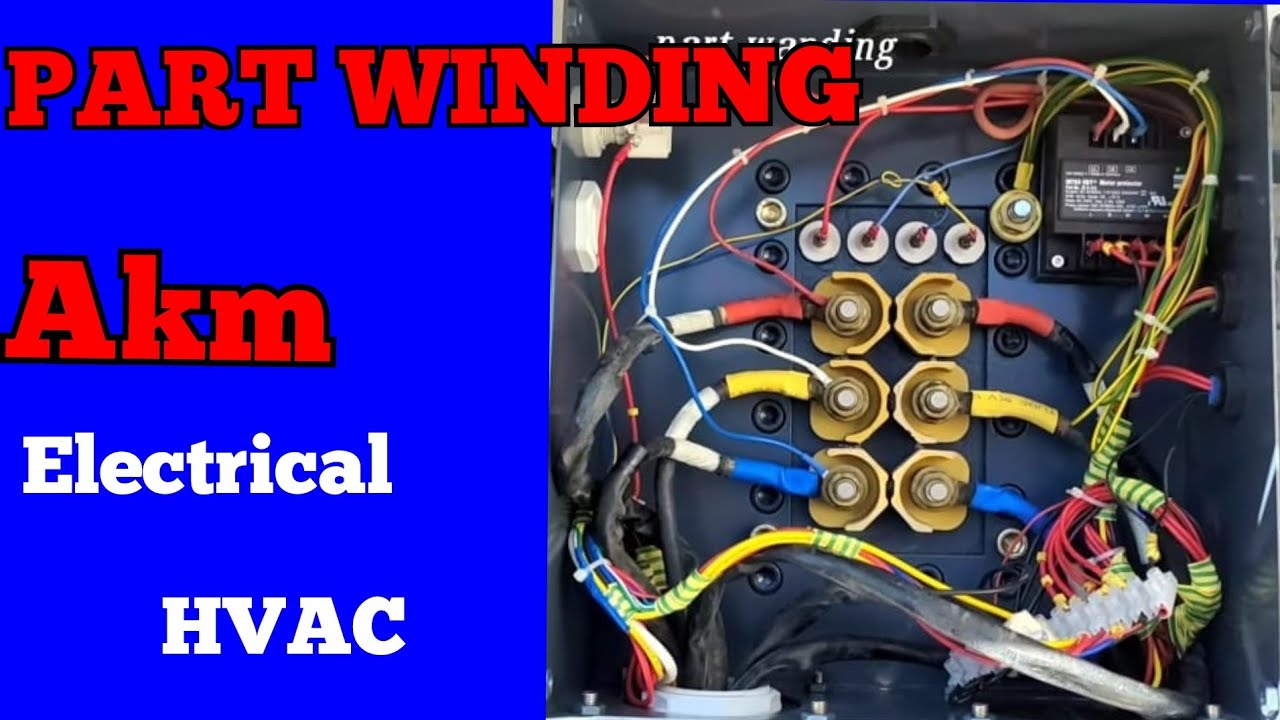

Oct 20, 2008. #4. No, a Part Winding motor starter is specifically for a motor configured for Part Winding (PW) start. Literally, the winding is split in two, so to start it you are connecting only a portion of it, then to run you connect the rest by just adding it in; no transition. There are two contactors, one for each part, and a simple timer.

Partwinding connection Electric motors & generators engineering

Part winding start is possible with motors whose stator winding is divided by design into 2 halves with 3 windings each. Both winding partitions lie parallel in the stator slots. During start, they are switched on one after the other, with a time delay of e.g. 0.5 .. 1 s.

part winding part winding power connection chiller power wiring screw

Double Delta. Double Delta. This method accomplishes the equivalent of reduced voltage starting by changing a delta connected winding from parallel groups to series groups during the start. It is frequently termed "double delta part winding" because it utilizes a standard part winding starter and has characteristics that are similar to the part.

Motor winding YouTube

If the leads are numbered 1-3 and 7-9, the winding is capable of part-winding start. When using a different starting method (e.g., soft start, variable-frequency drive, or across-the-line), always connect the machine for run. Some machines will have 1-1, 2-2, 3-3, which will be a delta-run motor (see Figure 2).

Démarrage part winding et comment lire une plaque signalétique YouTube

Part winding starters, ill. 1, are designed to be used with squirrel cage motors having two separate and parallel stator windings. In the part winding motor, these windings may be Y connected or delta connected, depending on the motor design. Part winding starters are not suitable for use with delta-wound, dual-voltage motors.